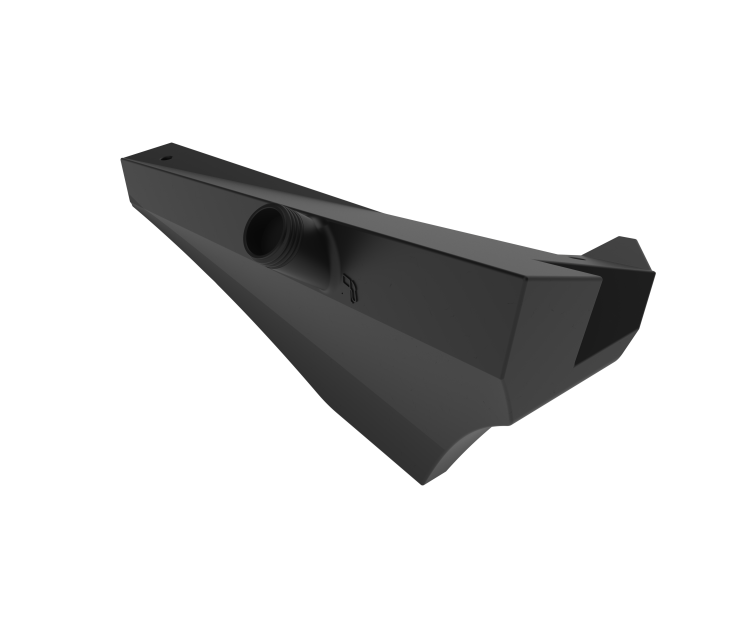

Oil and petrol tank integrated into the design

Oil and petrol tank integrated into the design

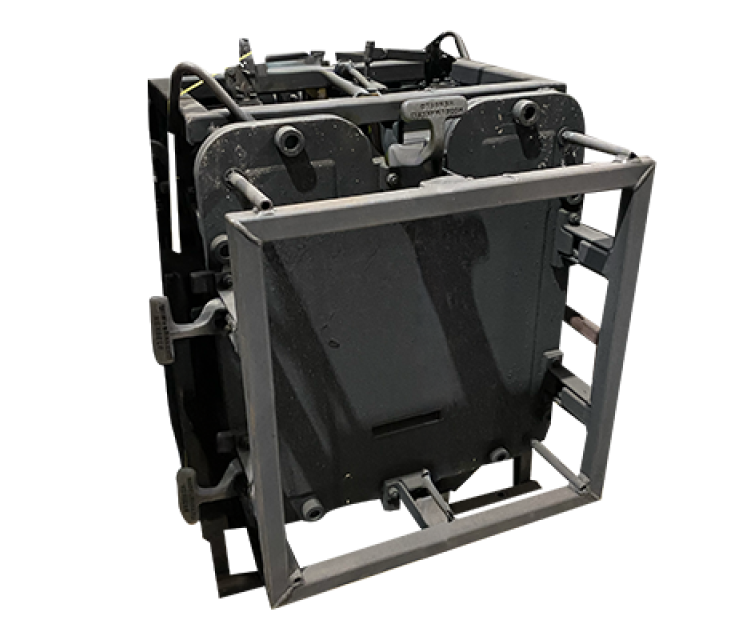

For this powerful shredder, we developed a tank that also serves as the visible bodywork of the machine. This multifunctional solution combines aesthetics and functionality in one sleek design. The tank can hold both hydraulic oil and petrol and is made of PEX (cross-linked polyethylene) – a material that is exceptionally resistant to chemicals and high temperatures.

Production process

This fuel tank is also equipped with all the necessary accessories to make assembly better, stronger and more efficient in a further production process.

Unique technical specifications

The thread on the petrol tank is made from cross-linked polyethylene.

What is unique about the petrol tank is that the thread is made from plastic. This project also uses special cross-linked polyethylene, which is resistant to petrol corrosion.

Moulds

Two moulds, the petrol tank and the oil tank.

High dimensional requirements, these must fit perfectly into the shredder as a whole, otherwise the lines and shape of the product will not be correct.

Realisation

The shredder's two tanks have strict dimensional requirements. They must fit perfectly into the overall design of the machine. This ensures that the lines flow seamlessly. We are dealing with two tanks with unique properties that combine to make the shredder a single functional unit.